Aluminum Foundry and Wisconsin Aluminum Foundry: building a strong future

Wiki Article

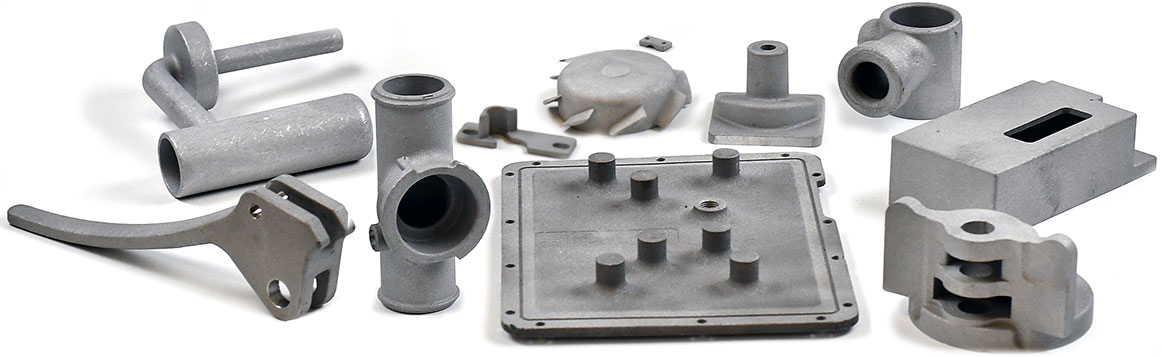

Discovering the Important Applications of Light Weight Aluminum Castings Throughout Different Markets

Aluminum castings play a vital duty in several markets. Their long lasting and light-weight features add to developments in auto and aerospace fields. Additionally, they enhance building and construction stability and consumer item style. As sustainability becomes a top priority, the environmental advantages of aluminum castings even more highlight their importance. Recognizing the considerable applications of this product can reveal insights right into modern manufacturing techniques. What certain developments are being made in these numerous sectors?Automotive Sector Innovations

Moreover, aluminum castings play a vital role in electrical automobiles, where weight decrease is vital for battery efficiency. With the assimilation of light weight aluminum in engine blocks, transmission housings, and architectural components, car manufacturers can achieve premium toughness while keeping peak efficiency. As the need for lasting and effective lorries expands, the vehicle sector proceeds to embrace light weight aluminum casting advancements, placing itself at the center of technical improvements and environmental obligation.

Aerospace Advancements

While the aerospace industry continually looks for methods to enhance efficiency and efficiency, innovations in light weight aluminum spreadings have actually emerged as a crucial variable in accomplishing these goals. The light-weight nature of aluminum significantly contributes to fuel performance, lowering total aircraft weight without jeopardizing architectural integrity. Advancements in casting methods, such as die casting and investment casting, enable intricate styles that boost the rules of aerodynamics and performance.Furthermore, developments in metallurgy have actually boosted the toughness and corrosion resistance of light weight aluminum alloys, making them suitable for different aerospace applications, consisting of engine parts and body structures. The capability to create complex shapes minimizes the variety of parts called for, enhancing assembly processes and reducing upkeep needs. As aerospace manufacturers progressively turn to aluminum castings, they are finding that these improvements not only drive functional performance yet additionally support sustainability goals via decreased energy intake throughout trip.

Building and construction Applications

Aluminum spreadings play a pivotal role in the building and construction market, using a combination of toughness, sturdiness, and light-weight residential properties that enhance structural honesty. Metal Castings. These castings are used in a variety of applications, consisting of window frames, door frameworks, and roof, where their resistance to corrosion and weathering is specifically useful. Aluminum spreadings add to power effectiveness, as their lightweight nature reduces the total load on frameworks, facilitating easier transport and setup.Additionally, the adaptability of light weight aluminum enables complex geometries and detailed styles, conference visual requirements without endangering architectural performance. In seismic areas, aluminum spreadings can be employed in critical architectural components, offering substantial benefits concerning versatility and strength. In general, using aluminum castings in building not just enhances the efficiency of structures but also sustains lasting building methods by allowing the use of recyclable materials in building projects.

Consumer Item Manufacturing

In consumer goods manufacturing, light weight aluminum castings play an essential duty in lightweight product layout, permitting easier handling and improved performance. Their improved resilience attributes contribute to the long life and reliability of day-to-day products. This combination of benefits makes light weight aluminum a preferred material in the competitive consumer goods market.Light-weight Product Layout

As producers progressively prioritize efficiency and sustainability, light-weight product layout has emerged as an essential aspect of durable goods advancement. The assimilation of aluminum castings permits designers to develop items that are not only lighter but likewise extra energy-efficient. This decrease in weight adds to lower transportation costs and improved individual experience, as consumers progressively seek easier-to-handle goods. In addition, lightweight designs facilitate cutting-edge looks, allowing brand names to differentiate themselves in a competitive market. The convenience of aluminum permits detailed forms and forms, improving overall layout flexibility. Light-weight product style is coming to be important for business intending to satisfy modern-day customer demands while sticking to ecological considerations. This trend is improving exactly how products are conceived and produced across numerous markets.Improved Durability Functions

While modern-day customers demand products that are both light-weight and visually pleasing, enhanced longevity attributes have become just as crucial in consumer goods manufacturing. Aluminum castings use exceptional strength-to-weight proportions, allowing suppliers to develop items that hold up against daily damage. The integral deterioration resistance of light weight aluminum assurances that products maintain their appearance and capability in time, minimizing the demand for regular replacements. Additionally, casting strategies make it possible for the production of smooth layouts that boost architectural honesty. Because of this, manufacturers can supply durable goods that not just meet performance assumptions yet also offer long life. This emphasis on durability not just improves client satisfaction but likewise straightens with sustainability objectives by reducing waste and promoting liable intake.Electrical and Electronics Industry

The electrical and electronics sector progressively depends on aluminum spreadings for their lightweight, sturdy, and highly conductive residential or commercial properties. These spreadings are indispensable in manufacturing different elements, consisting of real estates, units, and warmth sinks. Their low thickness permits for lowered overall weight in electronic tools, enhancing mobility without endangering performance. In addition, light weight aluminum's superb thermal conductivity is important for dissipating warm created by electronic components, making certain optimal operating and durability.Aluminum castings supply outstanding corrosion resistance, which is essential for maintaining digital stability in different settings. The capacity to develop complicated forms and detailed layouts through casting methods even more sustains innovation in product advancement, enabling makers to satisfy particular technical requirements. As the demand for energy-efficient and high-performance digital devices remains to grow, aluminum castings are positioned as a key material, facilitating improvements in innovation across the market. Their adaptability and integrity make them essential in the modern-day electrical and electronics landscape.

Sustainability and Environmental Influence

Recognizing the expanding problem for ecological sustainability, the aluminum spreading market has made substantial strides in minimizing its ecological footprint. The production of light weight aluminum castings currently increasingly utilizes recycled products, minimizing power intake and resources extraction. This change not only conserves sources however likewise reduces greenhouse gas exhausts connected with primary aluminum manufacturing.

Furthermore, improvements in technology have actually resulted in extra effective spreading processes, even more decreasing waste and boosting energy effectiveness. Numerous suppliers are embracing lasting practices such as closed-loop systems that recycle water and minimize hazardous waste.

Light weight aluminum's light-weight nature improves fuel effectiveness in transport fields, contributing to lower exhausts over the lifecycle of automobiles. As the sector remains to prioritize and innovate sustainability, light weight aluminum spreadings are poised to play an important duty in advertising eco accountable practices throughout numerous fields, straightening with international initiatives to combat climate change and promote lasting development.

Frequently Asked Concerns

What Are the Conveniences of Light Weight Aluminum Castings Over Various Other Materials?

Aluminum castings offer lightweight residential properties, outstanding deterioration resistance, and good thermal conductivity. Furthermore, they make it possible for elaborate layouts, reduce manufacturing costs, and supply boosted durability, making them beneficial compared to typical products like steel or iron.How Are Aluminum Castings Produced?

Aluminum spreadings are generated via procedures like sand casting, die casting, and investment casting. Molten aluminum is put right into mold and mildews, permitted to cool down, and afterwards eliminated, resulting in accurate and durable components for various applications.What Is the Common Life Expectancy of Aluminum Castings?

The common life expectancy of aluminum castings ranges 10 to 50 years, depending upon environmental elements, usage conditions, and alloy structure. Appropriate upkeep and treatment can substantially prolong their toughness and performance in different applications.Can Light Weight Aluminum Castings Be Reused?

Yes, aluminum castings can be recycled successfully (Metal Castings). The reusing process keeps the steel's residential properties, making it a lasting alternative for different applications, consequently contributing to environmental preservation and resource monitoring within numerous marketsWhat Industries Are Arising for Aluminum Casting Applications?

Emerging industries for light weight aluminum spreading applications consist of electric automobile production, renewable power sectors, aerospace advancements, and clinical technology. These sectors take advantage of light weight aluminum's lightweight, sturdy homes to introduce and enhance efficiency in various items and systems.While the aerospace industry constantly looks Wisconsin Aluminum Foundry for ways to boost performance and effectiveness, advancements in aluminum spreadings have emerged as an important factor in accomplishing these objectives. Aluminum castings play a crucial role in the building sector, offering a combination of stamina, durability, and lightweight properties that enhance structural stability. In customer items manufacturing, aluminum castings play a vital duty in light-weight item design, allowing for simpler handling and enhanced effectiveness. The electric and electronic devices industry progressively depends on light weight aluminum spreadings for their light-weight, durable, and highly conductive homes. Light weight aluminum spreadings are created with procedures like sand spreading, pass away spreading, and financial investment spreading.

Report this wiki page